Грешка у формату е-поште

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

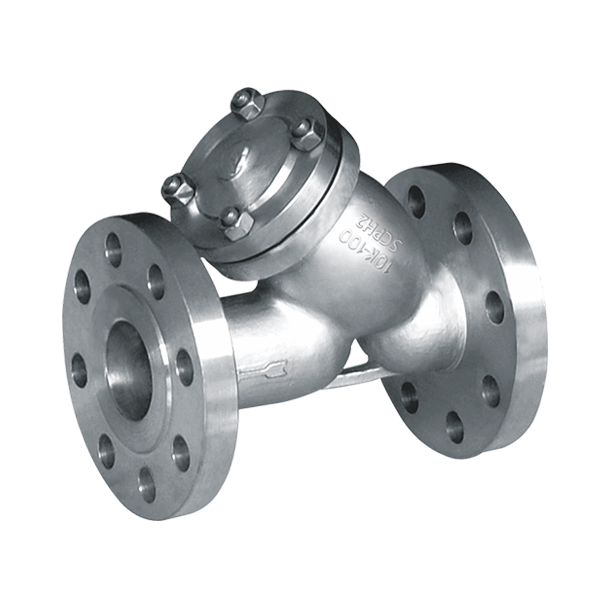

Y TYPE STRAINER

Y-type filter uses spiral cylinder filter cartridge to separate solids in liquid. The filter body is made of plastic or stainless steel. The screen consists of horizontal pipes with openings arranged in a row at predetermined intervals and installed above or below the tank to separate various substances from the liquid.

Product introduction:

The Y filter is a filter. It has a single inlet and outlet port. This type of filter is best used when it is necessary to control the flow, such as in a piping system. Y-type filter can be used as separation medium to screen out particulate matter from liquid or gas, because its network structure allows three separate discharge points: one for coarse material, one for fine material and one for clear liquid.

Y-type filter (also known as Y-type filter) is a kind of filter that uses spiral cylinder filter cartridge to separate solids in liquid. The filter body is made of plastic or stainless steel. The screen consists of horizontal pipes with openings arranged in a row at predetermined intervals and installed above or below the tank to separate various substances from the liquid.

Y filter is the most widely used in the process. The utility model has the advantages of simple structure, high efficiency and wide application range. It can be divided into: foreign matter filtration, low salt and low temperature water filtration and mobile measuring device. If the load is large or the application is complex, the synchronous operation of all inlet holes without auxiliary devices can be adopted.

Product advantages:

The Y-type filter is used to prevent product contamination by filtering out any impurities that may flow through the product. It uses a fine mesh that allows fluids to pass, but does not allow larger particles to pass. The Y-type filter can be made entirely of metal or plastic, the solid type is used for mechanical installation, and the open mesh type is used for chemical applications. Y-type filter is an industrial filter with large flow and large filtering area. The filter body is made of cast iron, and two parallel arms with filter screen are Y-shaped. The end of each arm is provided with a drainage tank for discharging the filtered materials.

Y-type filter is a horizontal filter, which can be installed on the main pipe of various transmission pipelines. This series of filters are characterized by small flow resistance, high efficiency, long drainage length and durability. It can be widely used in water and oil filtration, sewage treatment, etc. It is one of the most common devices used in filter type equipment. It is the typical operating performance or low-speed filter performance of filter type filter in industry, which can make the filter the most commonly used workplace.

Y-type filter is a unique and effective method to ensure product purity. The Y-shaped filter can withstand high pressure and the mesh is wide enough to ensure that debris can pass through. The most effective filters are those that can be used without affecting their efficiency. Therefore, this product is very suitable for industries where ensuring product stability is the key

Product design:

This Y-type filter is designed for industrial applications. The filter is widely used in chemical, metallurgical, petroleum, natural gas and other industries. The main body of Y filter is made of die-casting aluminum alloy, which has excellent impact resistance, thermal conductivity and rust resistance.

OVERVIEW: The Model YSF is a stainless steel Y strainer (wye strainer) that can be used in applications for steam, water, oil, or gas where protection from foreign matter in a pipeline is required. The YSF1 is 150# class, the YSF2 is 300# class, the YSF3 is 600# class, the YSF5 is 1500# class (RT flanges available), and the YSF6 is 2500# class (RT flanges standard).

They have flanges that are drilled in accordance with ASME B16.1, and perforated 304 stainless steel screens are welded along the seam for maximum strength. If the media is not specified, screens for liquid will be supplied.

Convenient gauge taps are furnished with a plug on both the inlet and outlet sides. These taps allow for easy installation of pressure gauges to monitor differential pressure to determine when screen cleaning is needed.

With its large body and sizable straining element, the YSF models provide excellent open area ratios that are typically two-and-a -half times larger than the corresponding pipeline, minimizing the pressure drop.

These stainless steel units are epoxy painted to help resist rust and corrosion. Stayflow also offers epoxy coatings as an option. They are also are available with different cover options, including swing, clamp, and hinge type covers.